Codonics Safe Label System (SLS) uses inkjet technology. Nowhere in hospitals is inkjet technology utilized because it is considered consumer-grade and inferior for important workflows. The pharmacy, for years, has used direct thermal printers for labeling all types of medications. The laboratory, for years, has used direct thermal technology for labeling specimens, blood bags, and testing items to ensure the quality of the label lasts throughout the specimen’s journey. Wristbands are printed largely using direct thermal printers today because of the importance of identifying the patient at key parts of their care journey. So, why does Codonics SLS use inkjet?

Inkjet consumables are expensive. Inkjet cartridges are incredibly wasteful. If the anesthesia provider prints mostly red or blue or yellow labels then the cartridge will exhaust itself sooner than its useful life suggests. This causes the hospital to replace the cartridge early driving greater waste and greater operational cost.

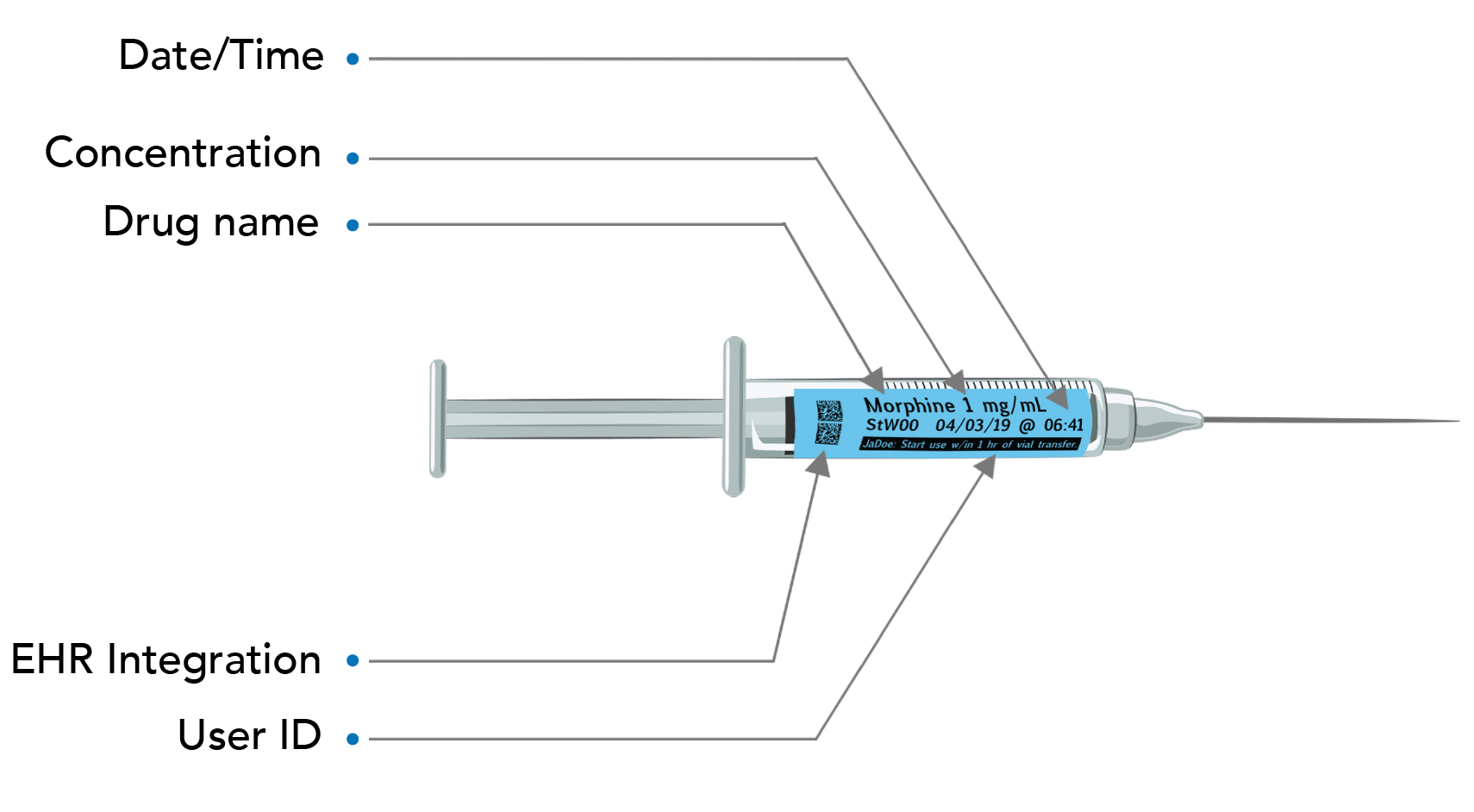

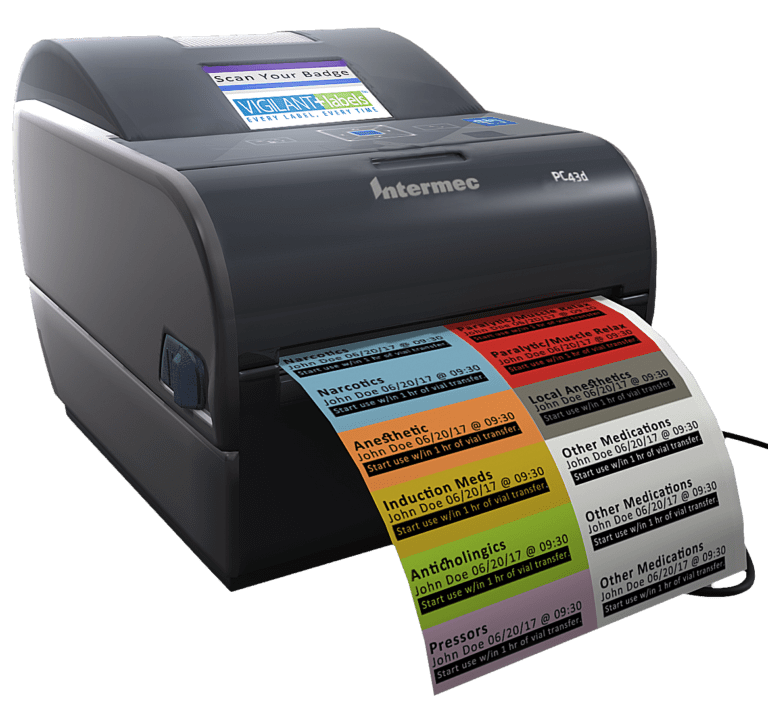

We know a better way exists. Thermal printers are more reliable and more suitable for operating room or other perioprative settings. That is why Vigilant built our solution using enterprise-class technology.